Development of a Solar Dryer for Drying Agricultural Products

Keywords:

Design and Fabrication, Drier, Alternative Energy, Plantain Solar Energy, Maize, Design and Construction, Moisture loss, Solar dryerAbstract

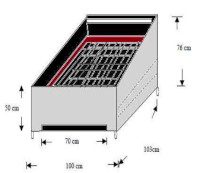

This paper describes a solar drying system that makes use of solar energy to heat air and dry any food substance that has been loaded into it. This system is effective in minimising agricultural product waste and aids in the preservation of agricultural products, among other things. Taking into consideration the drawbacks of natural sun drying, such as contact with direct sunlight, pest and rodent problems, lack of effective monitoring, and the increased high cost of the mechanical dryer, a solar system has been devised to address these issues. In this project, we will show you how to design and build a solar dryer system from scratch. The dryer is comprised of a solar collector (air warmer) and a solar drying chamber confining rack of three cloth (net) trays, which are both merged into a single structure. During the drying process, air is drawn into the drying chamber and heated by the solar collector. This heated air is directed through the drying chamber and used for drying purposes. The design was based on the geographical location, which was Edo State Polytechnic, the usen village in Ovia, in the south-eastern part of Edo state, and climatic data was acquired to ensure that the design specification was accurate. Wood, glass, aluminium metal sheet, copper, and net cloth for the trays were among the materials utilised in the construction, which was primarily made of locally available materials. The dryer operates at its most

efficient temperature of 50.500 degrees Celsius, with an ambient temperature of 34.5° degrees Celsius. The solar dryer was successful in removing 43.2 percent and 40.6 percent of the moisture content from maize and plantain, respectively, as compared to 28.2 percent and 27.89 percent from maize and plantain using the sun drying method, indicating a difference of 15.0 percent and 12.71 percent, respectively. The rapid rate of drying in the dryer demonstrates its ability to dry food items reasonably quickly to a high degree of consistency, as compared to the sun drying method.

References

Bahnasawy. A.J. and Shenana J.R. 2004. Evaluation of a solar crop dryer for rural application in Nigeria, Botswana Journal Technology 11(2); 58-62

Bena T.Y. and Fuller K.K. 2002. Determination of the average coefficient of internal moisture transfer during the drying of a thin bed of potato slice. Journal Food Engineering. 48(2) 95-101.

Bolako B.O 2005. Performance evaluation of a simple solar dryer for food preservation. proc.6th Ann. Engin. Conf. of School of engineering and Engineering Technology. Minna, Nigeria. Pp.8-13.

Ekechukwu I. and Norton S.D. 1999. Development and use of solar drying technologies. Nigerian Journal of Solar Energy 89: 133-64.

Enein N.E. 2000. Experimental investigation of solar air heater with free and fixed fins: efficiency and energy loss. International Journal of Science 1(1); 75-82.

Ertekin, C,; and Yaldiz, O. 2004, Drying of eggplant and selection of a suitable thin layer drying model, Journal Food Engineering 63:349-59

Hartmans, E.H. (1991). Strategies for Solving Crop Production Problems of Subsaharan Africa. International Institute of Tropical Agriculture, Ibadan. pp. 7- 8.

Ihekoronye, A.I. and Ngoddy, P.O. (1991). Integrated Food Science and Technology for the Tropics. Macmillan Publishers, Hong Kong. p. 386.

Ikejiofor, |.D, 1985. Passive solar cabinet dryer for drying agricultural products. In O. Awe (Editor), African Union of Physics, Solar Energy Conversion, University of Ibadan, Nigeria, pp.157-65.

Osagie, A.U. and Eka, O.U. [Eds.] (1998). Nutritional Quality of Plant Foods. Post Harvest Research Unit, University of Benin, Benin. pp. 34 -41.